Piecing tips from the art quilter!

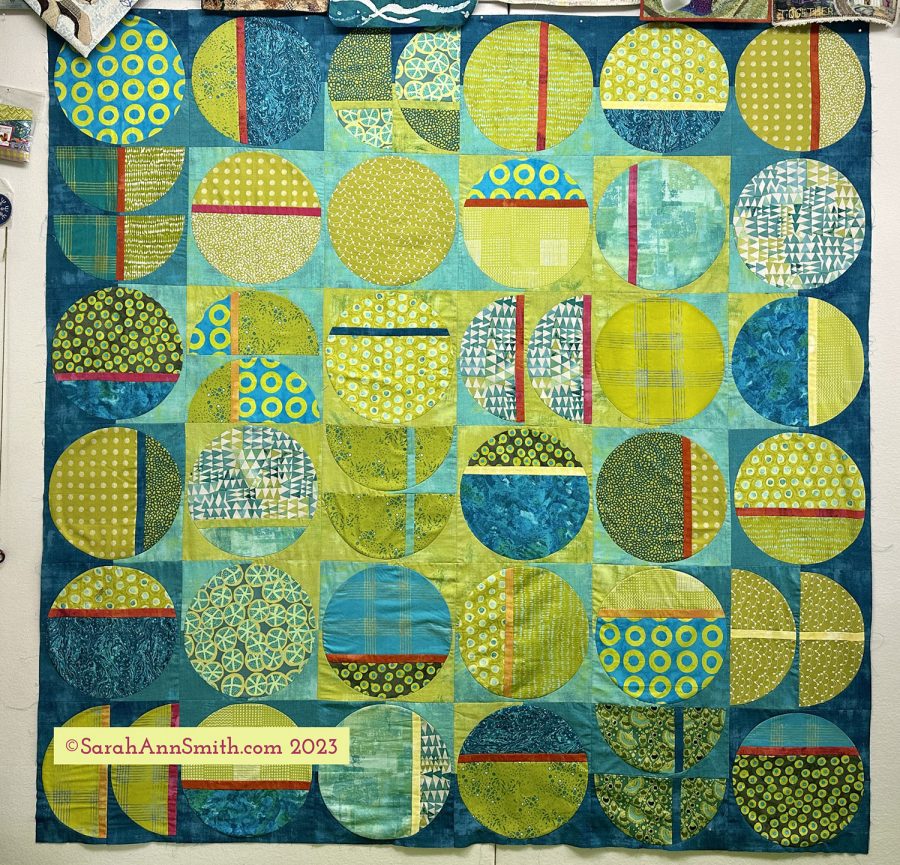

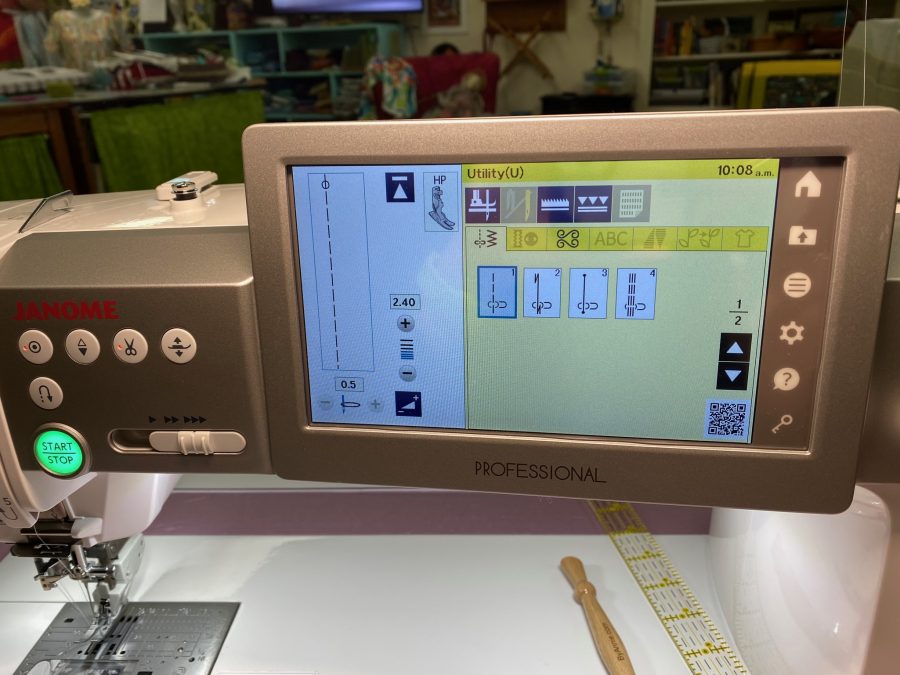

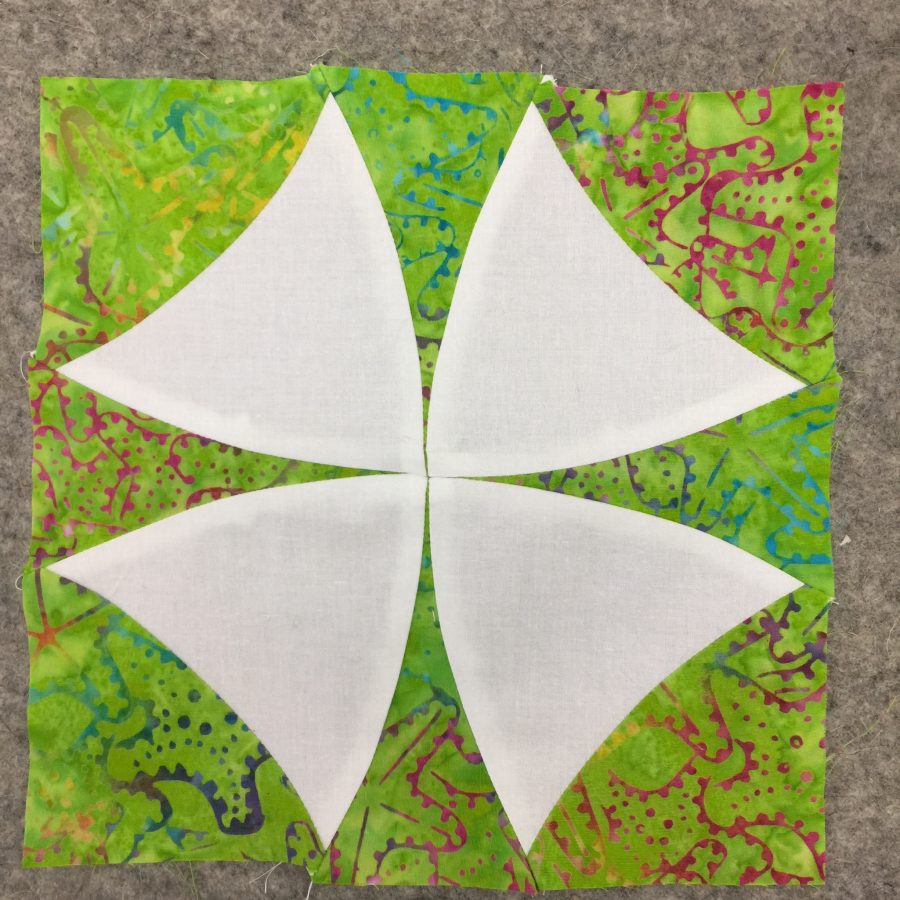

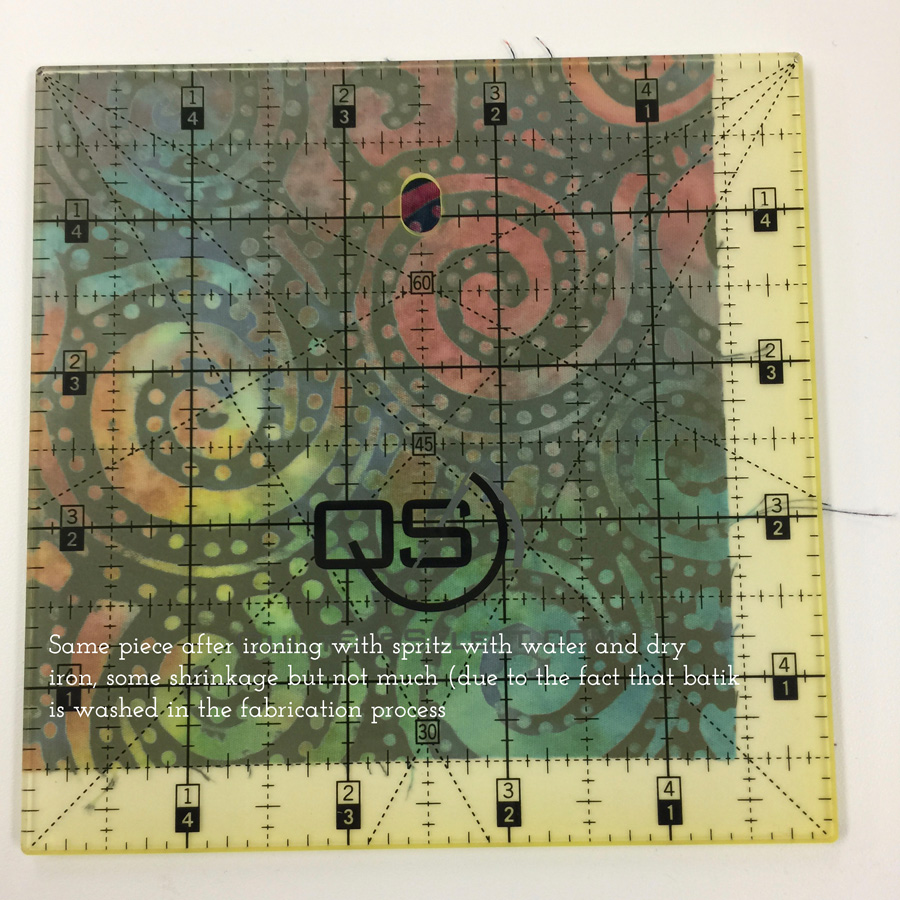

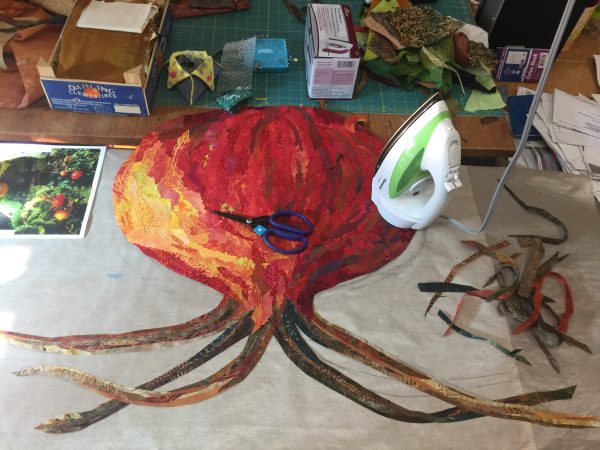

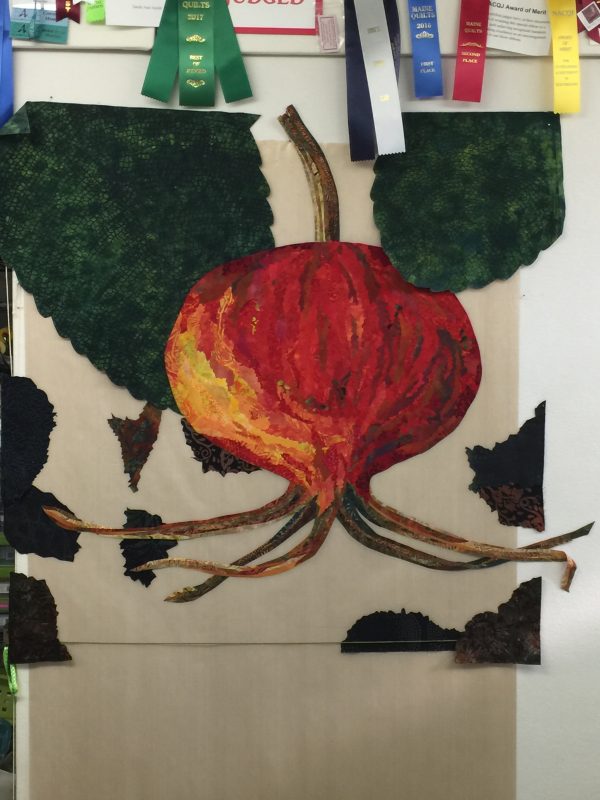

Saturday, September 9th, 2023First, hi everyone and welcome to new readers! I’ve actually been piecing…set-in circles no less! Above is the 74″ square top. Each block will finish at 12 1/2 inches. I used Latifah Safari’s 12″ Clammy to cut the circles, half circles and the corner quarter squares. Her instructions have you cut the outside from a single piece of cloth, but in addition to wanting to mix up the colors I felt that used too much yardage. I do have a nice stack of the background fabric “pumpkin seeds” from the leftovers to use in something, though! Need a title…not Crop Circles! Going in Circles? Nah… maybe Hither and Yon? My newsletters readers have come up with a few really good ideas… I’m narrowing in on a title but Help me here! Suggestions welcome! And if you’d like to get my newsletter, look in the menu bar on the right of the blog page (or at the bottom of any other page on this site) to sign up. If you live outside the US or prefer privacy, when it asks for a zip code just type in 12345 as a place holder–it works.

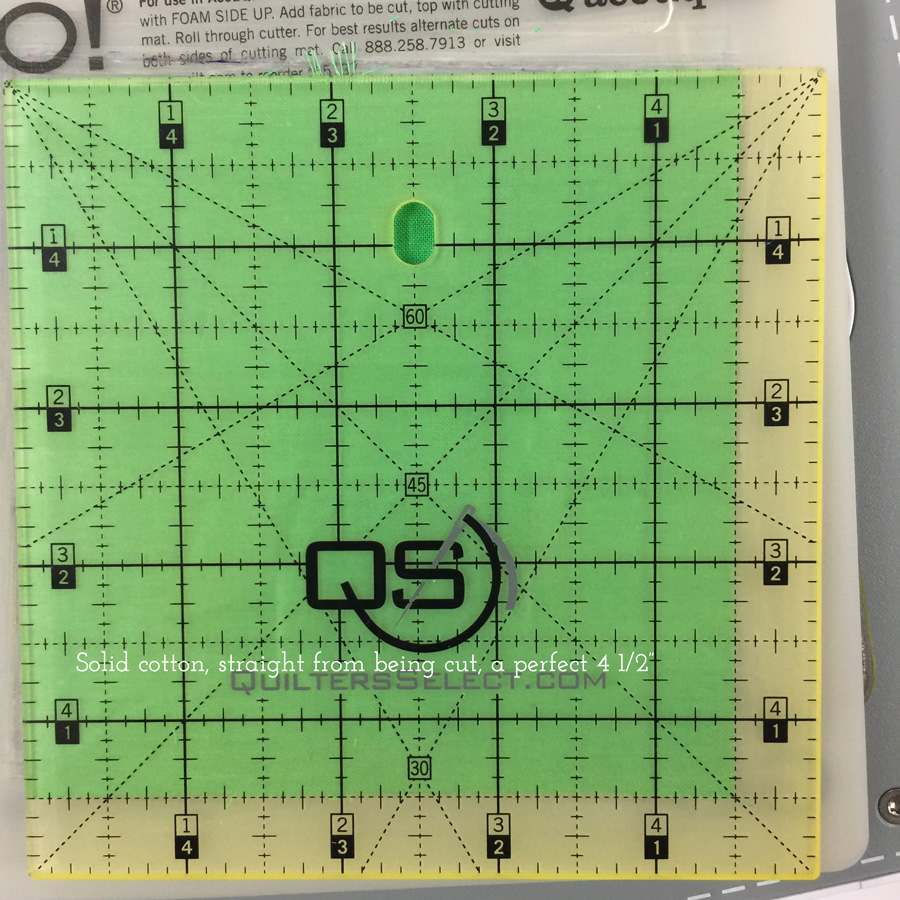

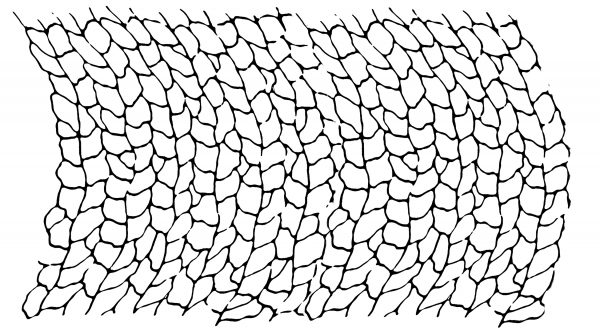

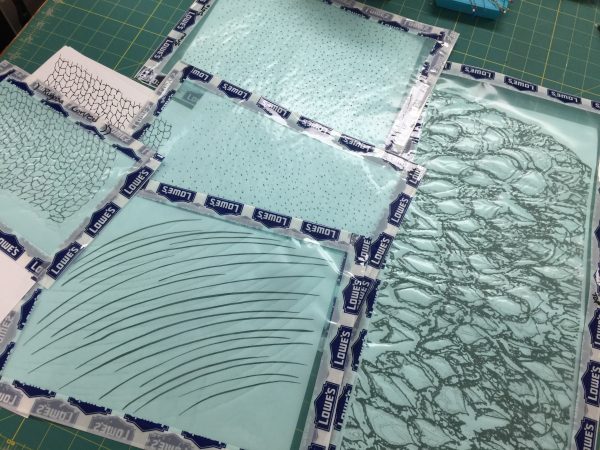

I love many modern quilts because of the large scale of the blocks (for a graphic impact rather than ease of construction, though that is a bonus too), the room for quilting and/or the use of straight line quilting, the color and, frankly, for a change of pace. I’ve also fallen for Latifah Saafir’s Clammy and Muffin Top quilts so I bought both the 8″ and 12″ templates. What I didn’t realize is how incredibly versatile her templates are, allowing you to make clamshells, half circles, muffin tops (about a generous 1/3 of a circle), quarter circles, background pieces, pumpkin seeds (that elongated football shape you see in the top right, and all the really useful markings to cut on the fold, add seam allowances and what not. In going to collect the hotlink for you, I noticed she has bundles that save on cost and also some seconds that are less expensive.

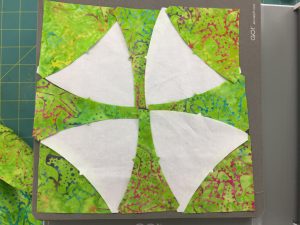

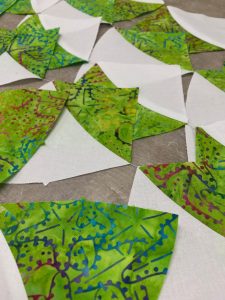

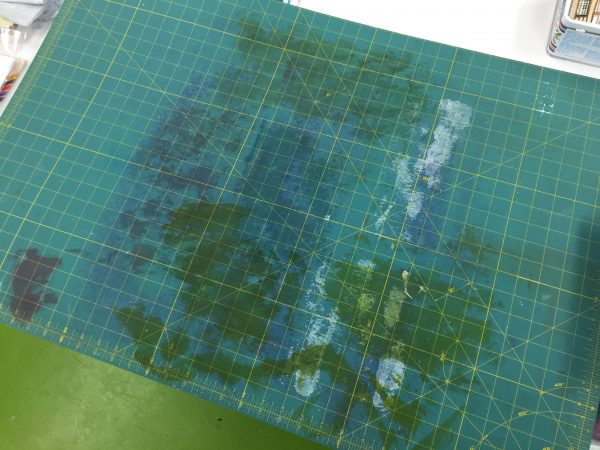

You can see that I used highlighter tape to mark where I needed to cut for my background. Her instructions have you cut a square, then cut from the square for the clamshell or circle. That gave me more odd leftovers than I wanted, so I cut the circle from the edge of my fabric and then cut four corners so I could mix up the background as well as save on scraps. Still, I’ve got a use for the leftovers….stay tuned (probably in a year LOL).

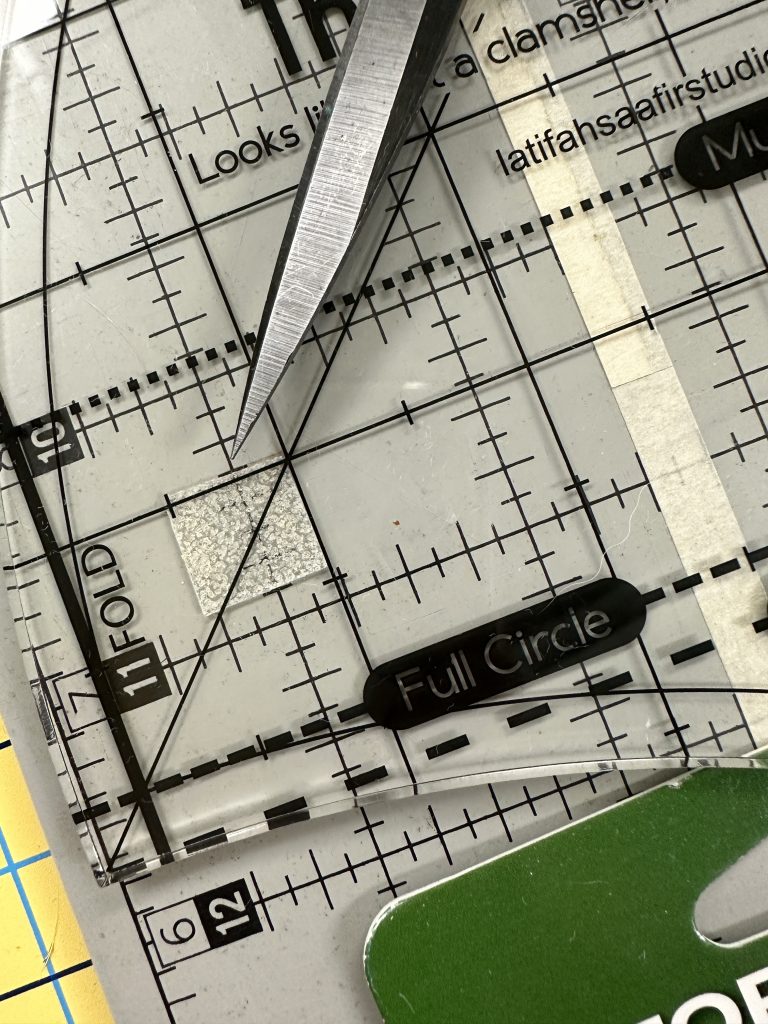

A longarmer recommended the Gator Grip tape to me; got it on Amazon to use for ruler-work machine quilting rulers, but it works for cutting rulers too. I found that I wasn’t able to hold the template without making it slip sometimes, so I cut four small squares of the grip tape. You can’t even hardly see it in this photo. See the next one for a close up. I LOVE THIS on the templates! You can still see the lines on the mat beneath the clear grip tape. It works better than the sandpaper dots and other products I’ve tried, and a roll of this stuff will last forever.

The scissors are pointing to the 1/2″ square of grip tape on the under side of the ruler. You can even (slightly) see the markings on the cutting mat through the tape! Also notice the helpful makings on the ruler for various extra ways to use the template for cutting things other than a clamshell.

Cutting and Precision

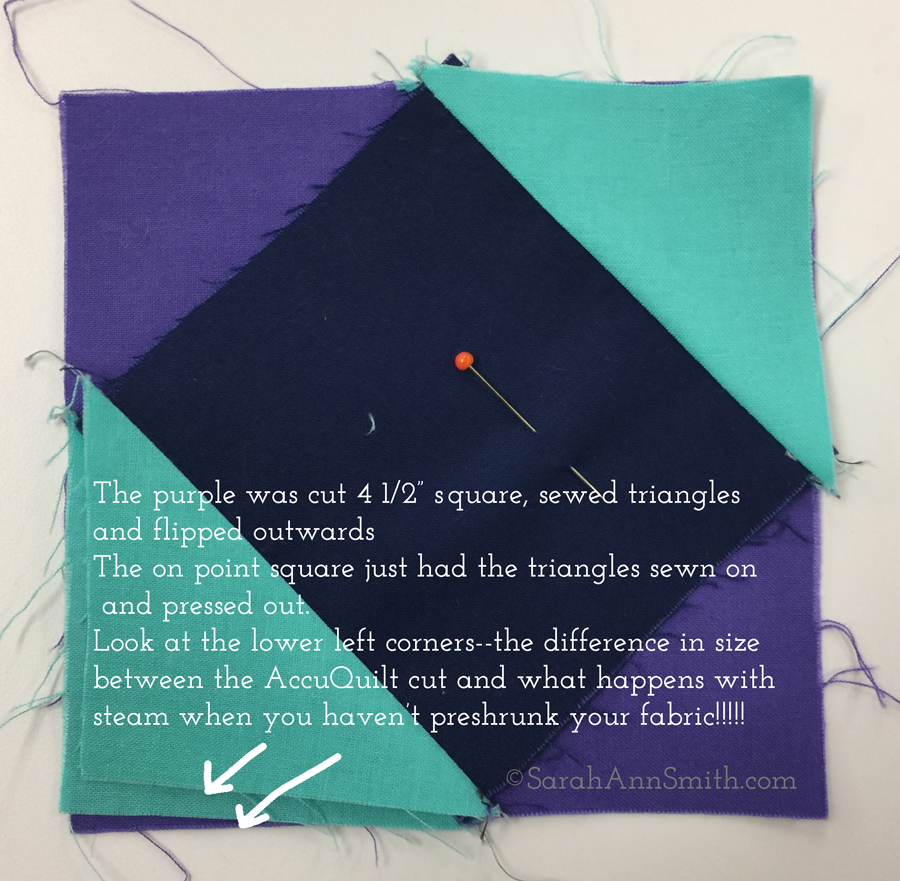

Let me just say “perfectly precise” are two words that have never been used to describe my work. But I am trying and learning. An online master class in International Quilt Festival’s Virtual Festival (it was in either December 2020 or 2021) with Philippa Naylor showed me I really COULD be precise if I tried. First, slow down. Second, cut as carefully and precisely as you can. If the pieces aren’t exact, then nothing else will be!

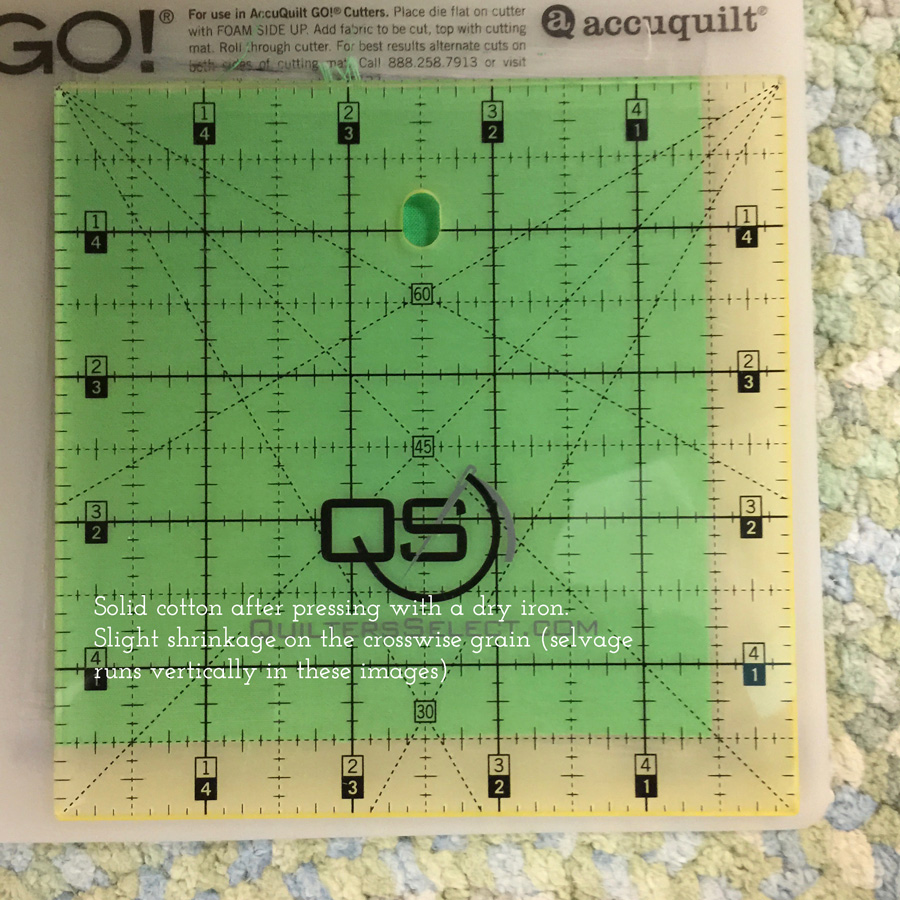

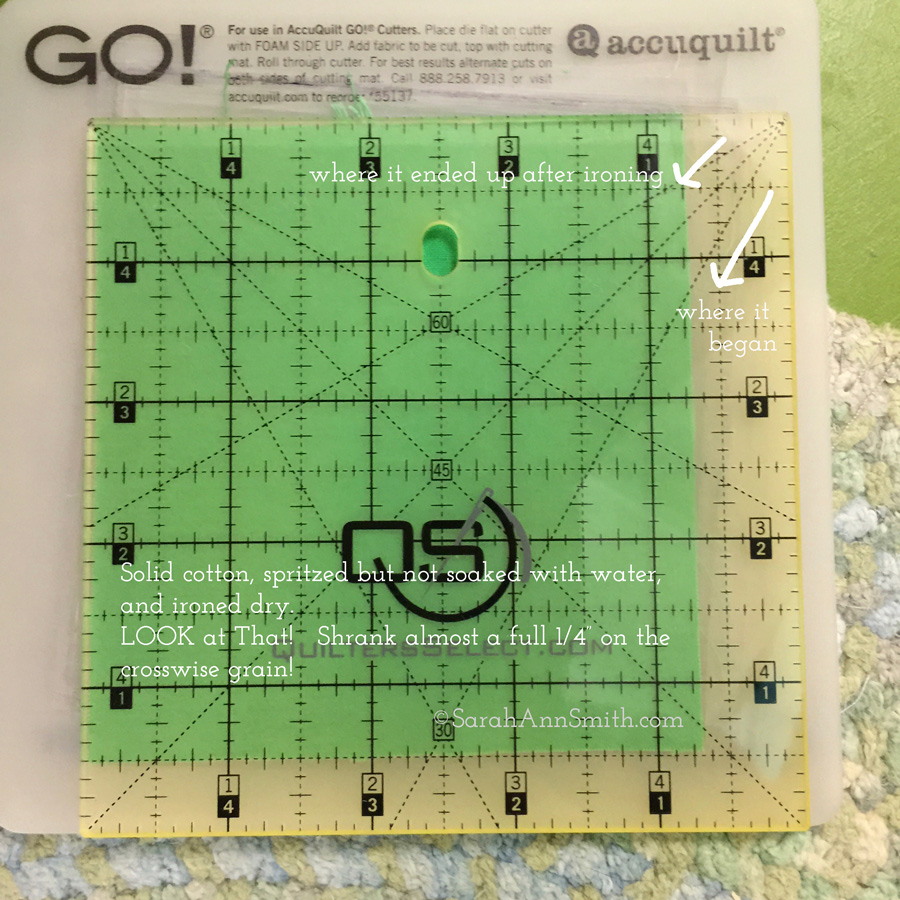

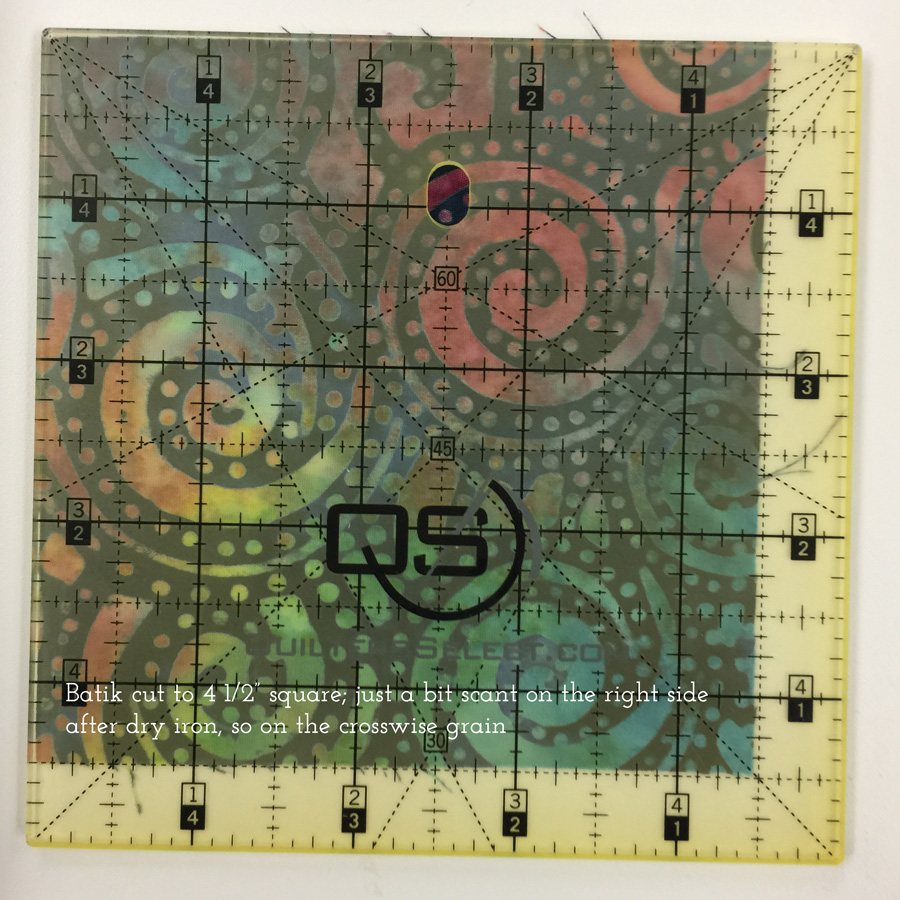

Pressing is also super important. To avoid tucks when pressing seams to one side, use the tip (or toe if in the UK) of the iron, NOT the side of the iron. Astonishingly, it really is more precise at getting the entire fabric pushed away from the seam without an inadvertent little fold or tuck. Sometimes, though, it is better to press seams open, and that takes a bit of learning when and how. I’ve taken Philippa’s online Garment Makers’ Question Time workshop, and think in a year or so (if/when I get caught up on everything else) I may take her Quilters Question Time, even with as many years of quilting as I have–egads coming up on 33+ years!

It’s amazing how nice and a FLAT I got the blocks–precise cutting, careful sewing, smart ironing for the win!

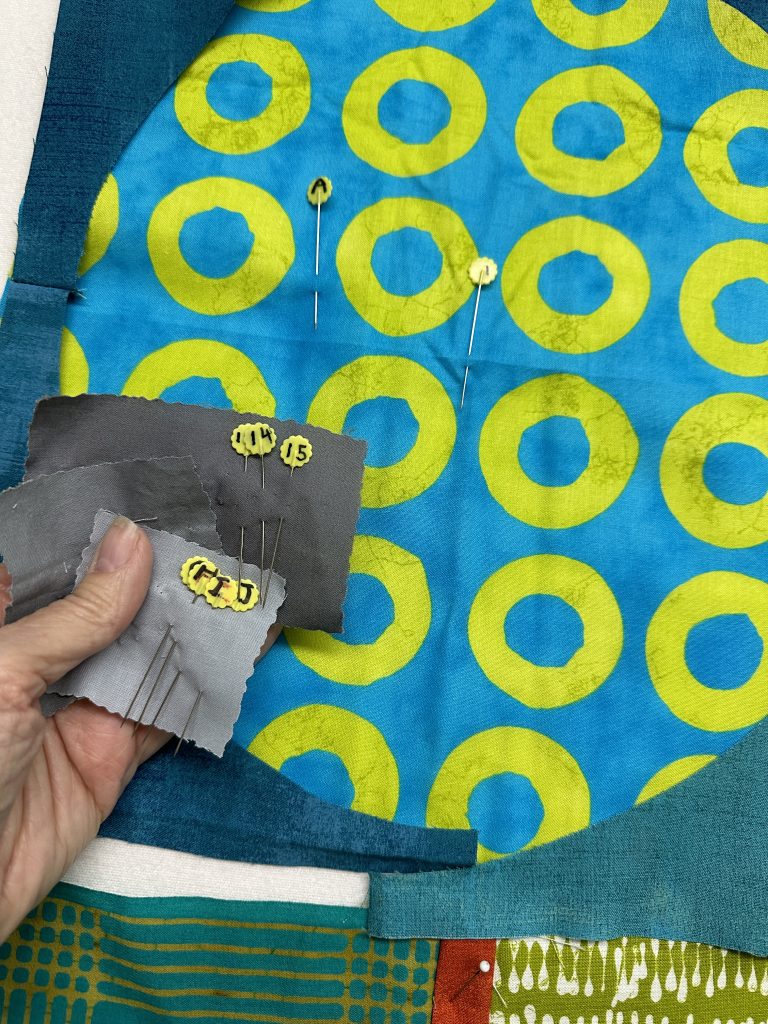

- Stitched blocks front and back. I used my alphabet and number pins to keep track of column and row. I placed a pink pin (Taylor Seville’s Magic Pins…the pink are the LONG ones) in the top left background quarter to help me keep track of placement. The letter/number pins are pinned vertically with the flower toward the top of the block, also to help me remember which way is up. Pressing: the background sections are pressed open. The stripe inserts are pressed under the strip. The background goes under the circle.

- I used a Sharpie to mark A,B,C etc. on some flower head pins, and 1-12 on even more. Each row is A, B, C etc., then each block going across is 1, 2, 3 etc.

- Fold the circle in half exactly and press a crease on the edges. Open it back up.

- Turn the circle 90 degrees, fold in half the other way aligning the first pair of crease marks, then iron in the second set of creases at the fold. At first I just quartered the circle and pressed, but I got more accurate alignment after I tried marking the spots in two steps.

- I pinned the background (sewn into a circle) to the center circle on the creases at the top, bottom and sides. In other words, the concave (innie) curve goes on top of the convex (outie) curve. As I stitched I added a pin about 1 1/2″ before each of those pins–the fabric doesn’t ease in as well where the grain is closer to on-grain. In the rest of the quarter circle arc, I use my fingers to ease in and hold the background in place.Being as accurate as you can at all steps helps!

In the studio I love my Zirkle magnetic pin minder, but this Clover magnetic pin “cushion” with a lid (that fits on the bottom when you don’t need the pins covered) is perfect for retreats and travel.

You can never have too many pins. For hand appliqué, you want them short so the thread doesn’t tangle. For machine piecing, I prefer really LONG so the head of the pin doesn’t get caught under the foot. ALWAYS pull the pin out before it reaches the needle–sometimes that maybe when it is one stitch away, but don’t sew over it. If you hit the pin you can knock the machine out of timing (expensive repair!).

My sets of homemade ABC and 123 pins are on the bottom, along with some of my Taylor Seville pins. Taylor Seville reached out to me when I was teaching at a couple shows in the past year or so, and sent me some to try (I hadn’t used them before but now I do!) and more to share as classroom giveaways. The pins come in different lengths and thicknesses. The mint green ones are the shortest of the ones I have, the blue are a finer metal (makes pinning seam allowances open flatter and therefore sew up more accurately, but they bend more easily so choose your usages wisely), the pink are longer. I prefer the longer as the grippy ends don’t get snugged under the presser foot. Best of all, Taylor Seville is coming out with a BOX of ABC 123 pins with SLOTS for each one… no more pinning into cloth or having a muddled mess of pins….. I always figured why spend the $$$ when I could make my own cheaper, but that organizing box is Da Bomb! Will be ordering as soon as they are available! I saw maybe September 2023 for them…..

PERFECT intersections!

Pinning is the key, with a big helping hand from seams pressed OPEN:

- first, put one pin through the Very Center of the seam of the pieces on the top,

- then poke that pin through the seam of the pieces on the bottom.

LEAVE the pin in the seam vertically–don’t bend it sideways or “pin the seam.”

- Place two more pins in the seam allowances on both sides of the seam.

The pin through the seam stays poking up!

- Slide the fabric under the presser foot and try to keep the vertical pin in place.

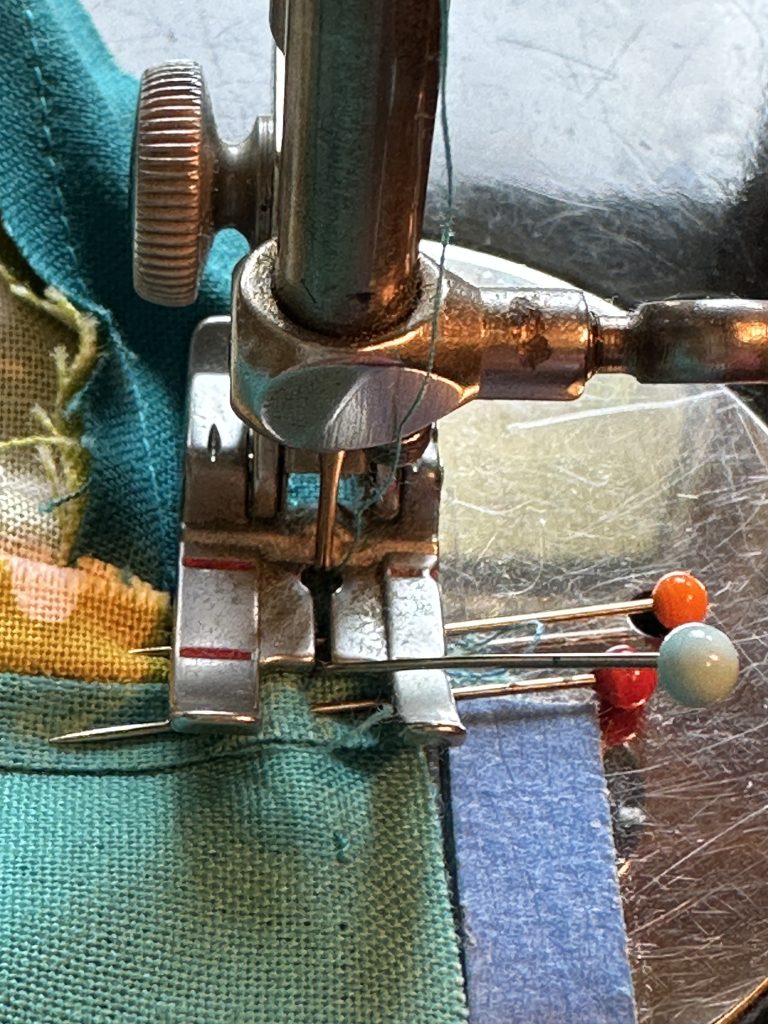

In the photos, below, you see that at a certain point you need to let the vertical pin pivot out of the way. The photo on the right shows me holding the pin still IN the seam to keep it aligned until the very last moment.

Sew SLOWLY when you approach all those pins. The finer the pins (in this image I’m using glass-headed pins that have a thicker shaft -metal part). The thinner the shaft, the more flat the fabric remains and the easier it is to get a perfect match. The drawback to finer pins is they bend more easily. Do what works for you. For me, I’ll sacrifice a few pins (and use them bent for a long while too) to get flat and perfect and not have to rip out and re-do.

I counted up on the horizontal seams that joined the rows (see top photo) and counted about 50 intersections. I only had to “fine tune” (i.e. fix) three, and even before fixing the perfect match was off by only a thread of two! Since I am nowhere near a perfect or precision sewer, that is nearly a miracle! I mean look at the next photo…SWOON!

Since I wrote my newsletter, I got the backing made from leftovers (hooray…about 2″ of stash used up…sigh…..).

Since I wrote my newsletter, I got the backing made from leftovers (hooray…about 2″ of stash used up…sigh…..).

I LOVE my long closet. When we moved in in 2011, this room was awful and unfinished. I had a carpenter make me sliding design-wall doors and I love them. They hide clutter (teaching stuff, storage for mixed media, paper, ribbons, etc., and all my quilts, rolled). Use the search box at right and enter “state of the studio” to see the transformation pictures.

And because we all need cute AND perfect intersections in our lives, I’ll close with Percy, who hopped up on the top the instant it was done to approve of the design!