Everyone’s a Kid Floor Cushions and Toss Pillows (part 1 of 2)

Monday, March 9th, 2020Today’s projects are floor cushions and toss pillows from Michael Miller’s adorable new fabric line, SuperFred and Space Pals. As soon as I saw them I knew I’d love to make some floor cushions for my daughter-in-law’s Kindergarten classroom! You can find part 2 here as of March 12, 2020.

With the help of my trusty (just try to pry it out of my cold dead hands! I’m taking it with me) Janome M7 Continental, and some experience having done custom home dec work in a previous life, sewing these cushions was easy, and I’d like to share a free pattern for Everyone’s a Kid Floor Cushions and Toss Pillows with you and show you just how easy!

Super Fred! Ask for the collection at your local shop!

Fabric requirements are at the bottom of this post and on the free pattern (link in the previous paragraph). The pattern also has all the other “stuff” you’ll need (zipper, interfacing, and so on) and ridiculously detailed instructions. I will focus on bigger pictures for the “how-to” things in this and my next post even though there are plenty of photos in the pattern.

My Deep-Pocket Placket

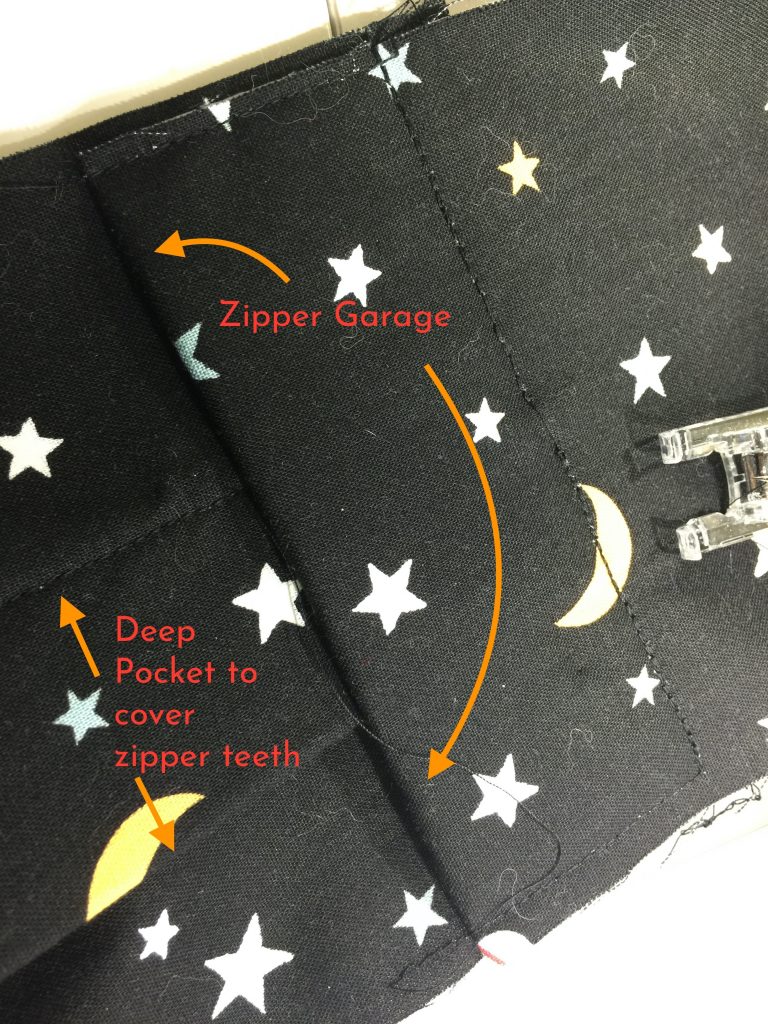

So many home dec books and pieces of furniture are made with skimpy zipper plackets that gap open and show the zipper teeth–boo hiss! The designer for whom I worked eons ago had *very* high-end clients, so I developed what I think is a much nicer zipper method. Yes, it uses a couple more inches of fabric, but the zipper is fully concealed, doesn’t gap, and even has a little “garage” at the end to hide the zipper pull. I have leftover (miles of leftover) upholstery zipper tape and pulls from doing custom home dec work, but you can order #5 weight zippers or use heavy duty zippers available at big box stores.

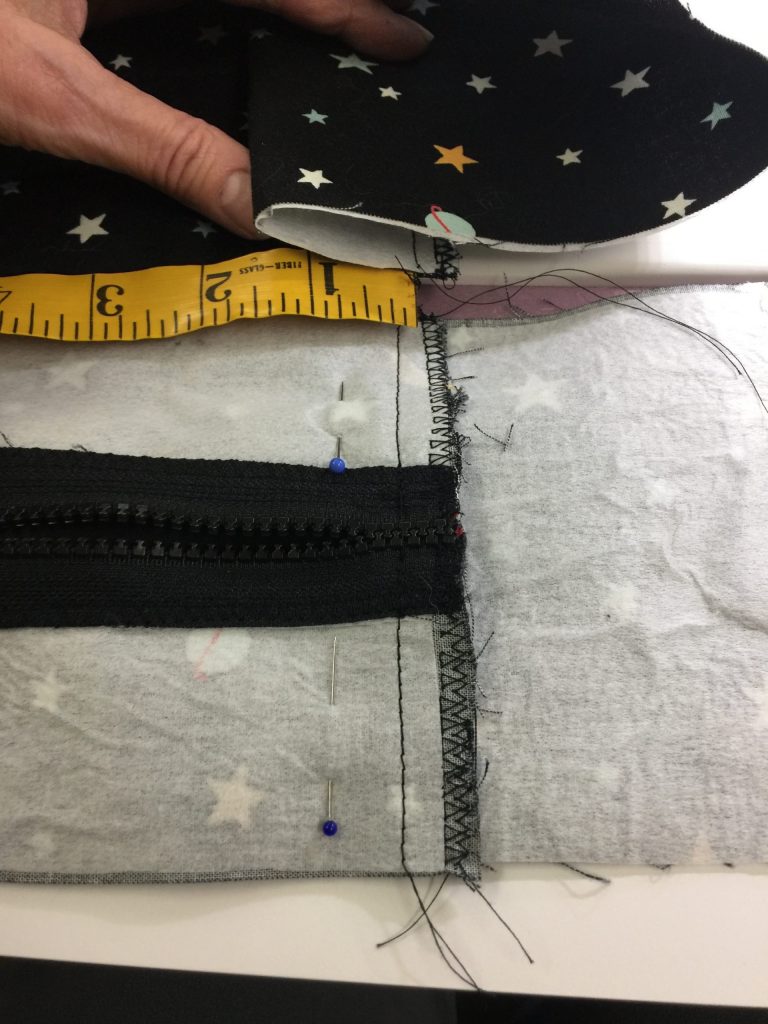

The pattern has exact cutting dimensions for the finished zipper gusset (the section of the boxing/sides of a cushion that has the zipper), but honestly I usually cut my strips about an inch wide than I think I’ll need. This gives me some fudging room to get the zipper centered. Once the zipper is sewn in, then I trim it to the desired finished measurements and complete making the gusset.

For this project, I knew the cushions would get a LOT of wear and tear, so I decided to reinforce all of the quilting-weight-cotton fabric with mid-weight fusible interfacing. Then I began assembling the components starting with the zipper. Of course, I was so excited to get started that the interfacing isn’t (yet) on the fabric shown below….I fixed that!

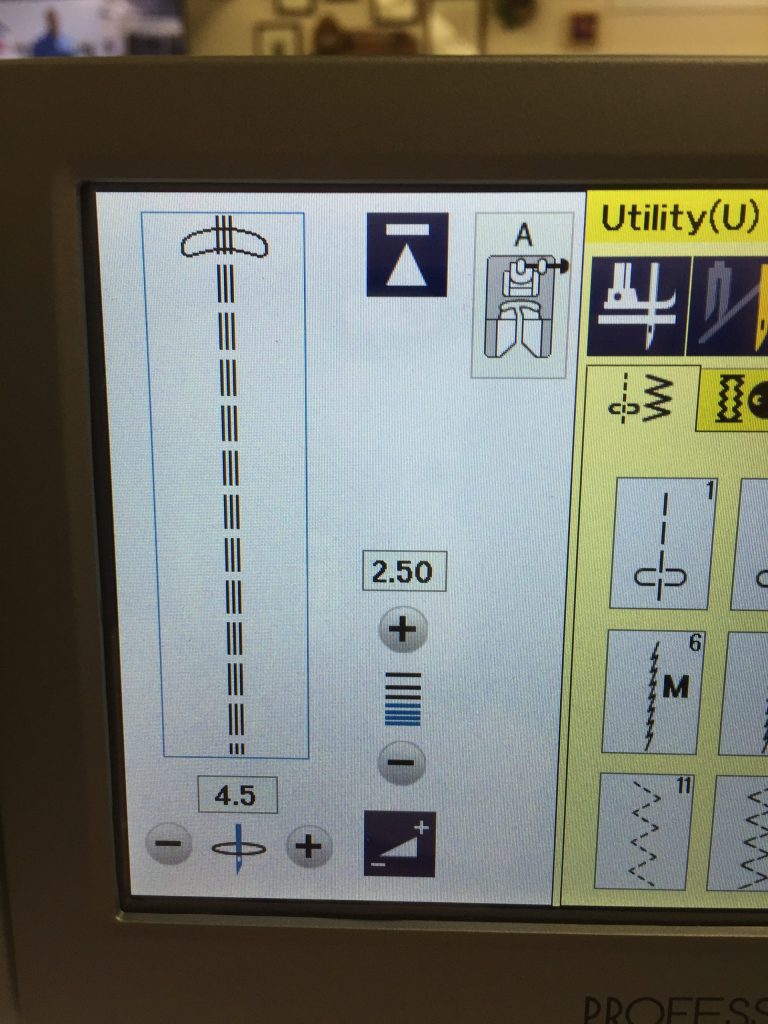

The video below shows me using the Janome M7’s “M” foot. Most machines have something similar. The three little wires help hold the fabric flat, the blade keeps the stitch perfectly positioned on the edge of the seam so you get a good-looking, functional, and non-puckered stitch.

Next, sew the wider upper side of the zipper gusset to the zipper tape using the edge-stitch foot only–you don’t need to do the straight seam close to the teeth as you did with the lower side of the gusset.

Your next step is to attach the rest of the boxing a.k.a. sides a.k.a. gusset–the fabric that goes around the edge of the cushion. First, use the overcast foot to sew the ends together. BE CAREFUL to NOT stitch through the ZIPPER TEETH! Just lift your presser foot and move over the clunky zipper teeth before finishing that seam. Repeat on the other side.

Make the first of the little zipper garage / pockets at the zipper ends. You really only need one at the closed end, but I like the cushions to be symmetrical (about the only time I love symmetry in my work!) so I do both ends the same way. In the photo above, you can see that I have made a pocket about 1 1/2″ deep by making a Z-fold (or S- depending on which side you look at). Pin in place (lower part of photo above) and then stitch a straight line about 1/2″ from the raw edges.

PHEW…that’s Zipper Wisdom according to Sarah. We are now blessedly done with the zipper–I swear it takes longer to explain it in writing than actually do it…well except for the fussing to make sure it is absolutely perfectly straight and nice! In my next post I’ll show constructing and stuffing the floor cushions. And, there are TONS of photos in the pattern, too. One more time, here’s the PDF for the Everyone’s a Kid Floor Cushions and Toss Pillows. Check back in 3 days for Part 2!

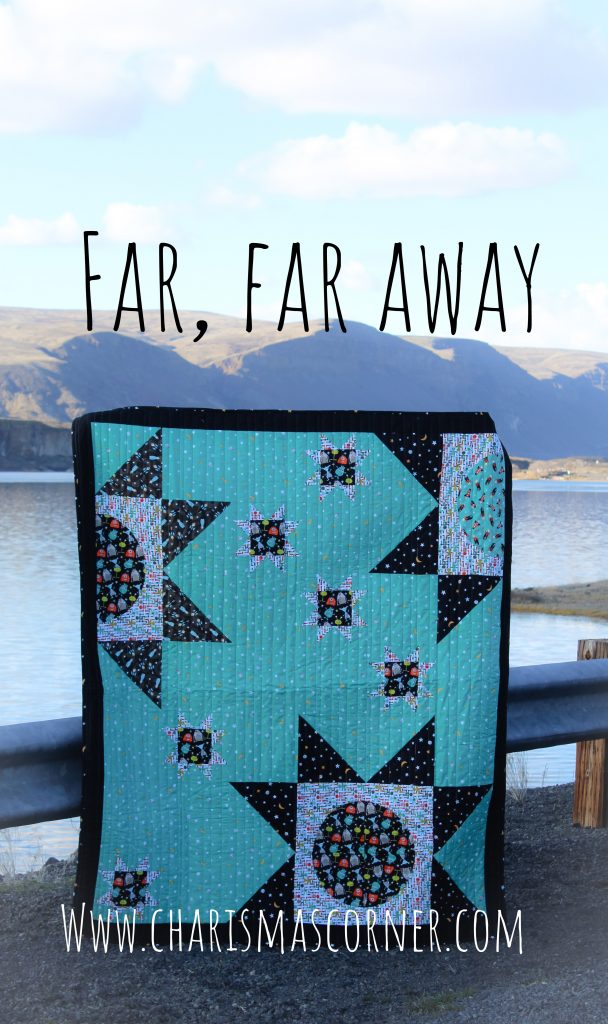

And one last minute goodie–my fellow Brand Ambassador Charisma Horton has made this adorable quilt out of different color ways of Super Fred–what a great combination for a kiddo: my cushions and pillows and her quilt! Check it out here on her blog, or the Far, Far Away pattern in her Etsy shop, in both download or paper versions.

Both print and digital versions of Far, Far Away are available in Charisma’s Corner Etsy shop, here. Go to page 3 of the Etsy shop and scroll down to find the patterns.

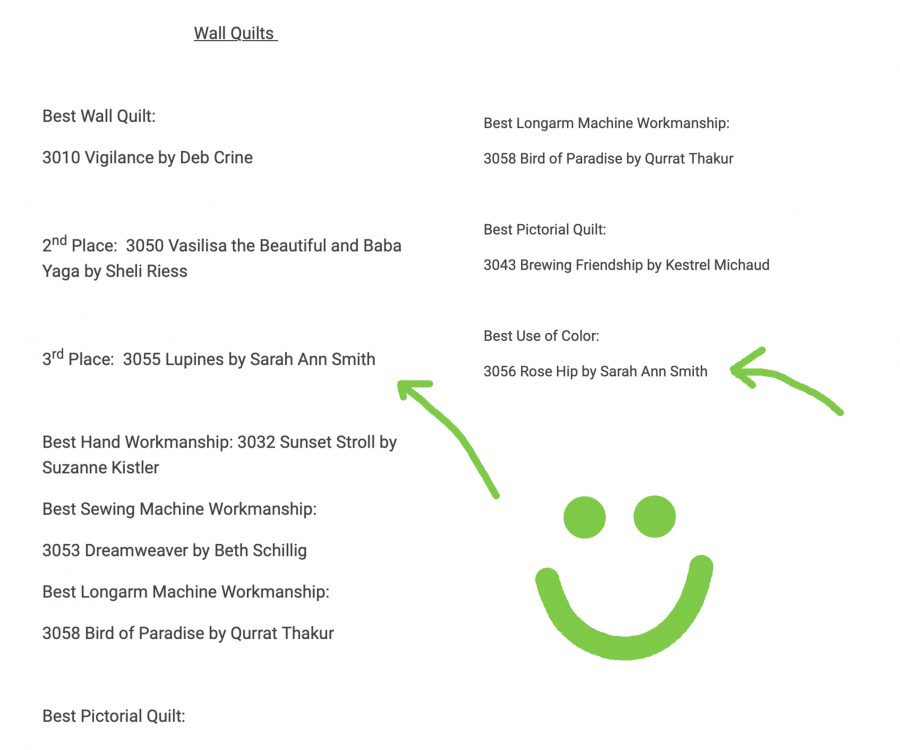

Fabric requirements for two 24” square floor pillows and two 14×20” toss pillows:

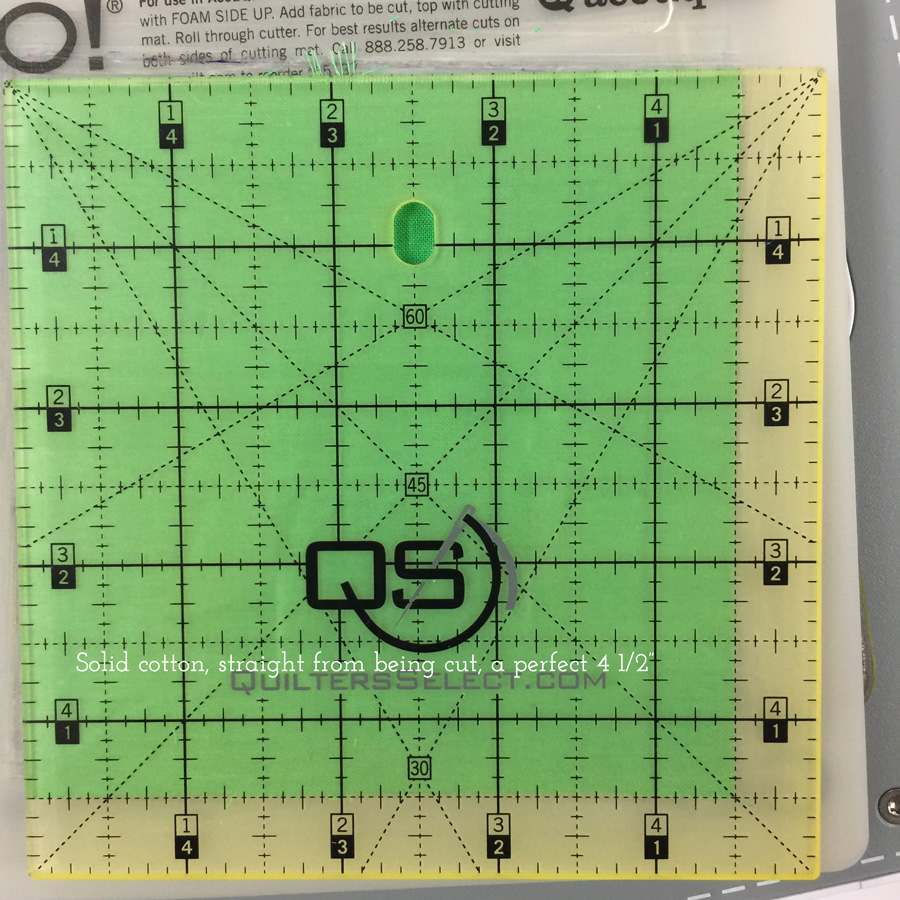

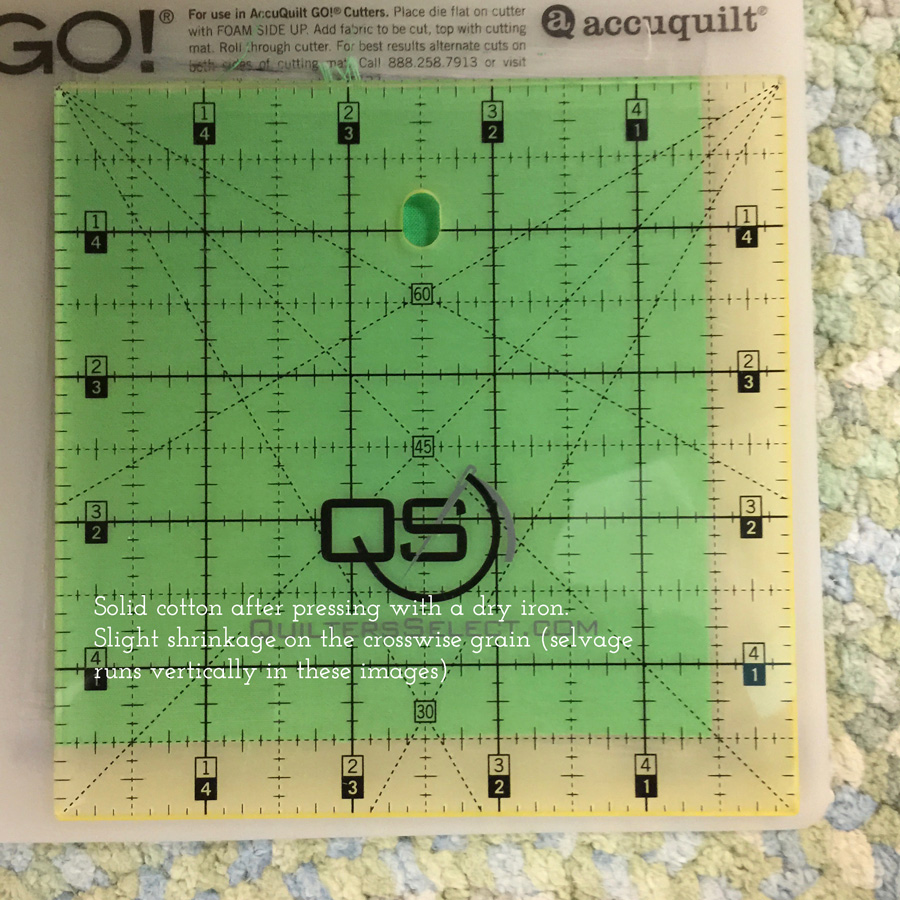

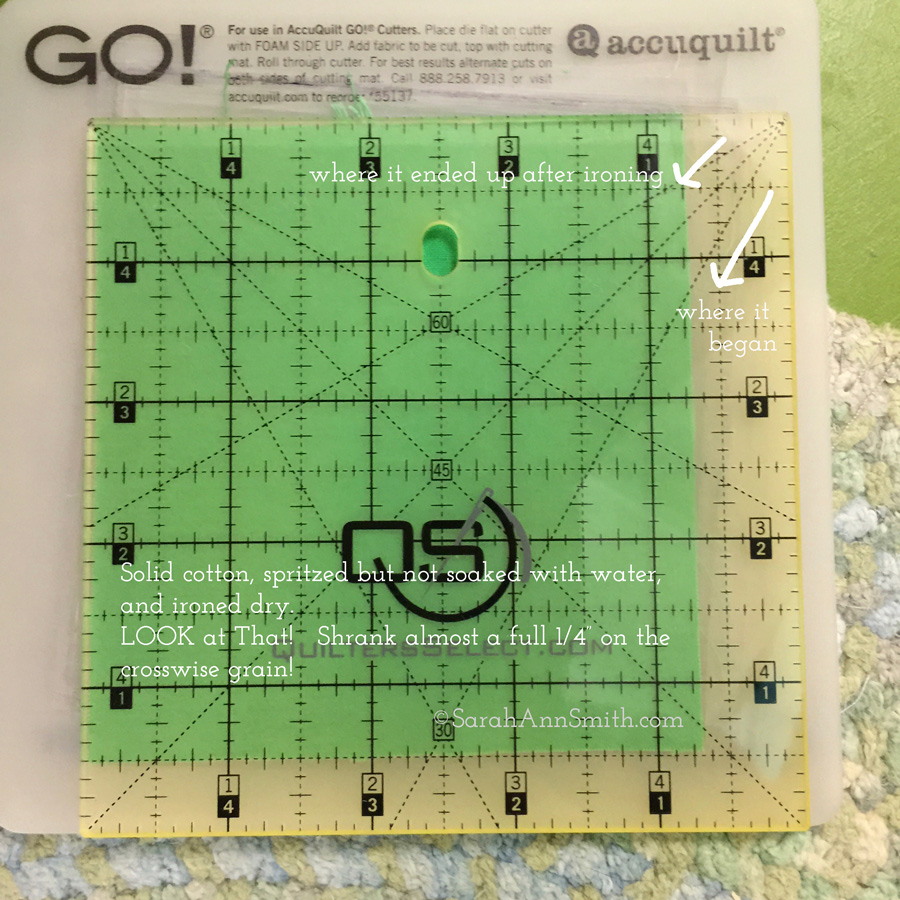

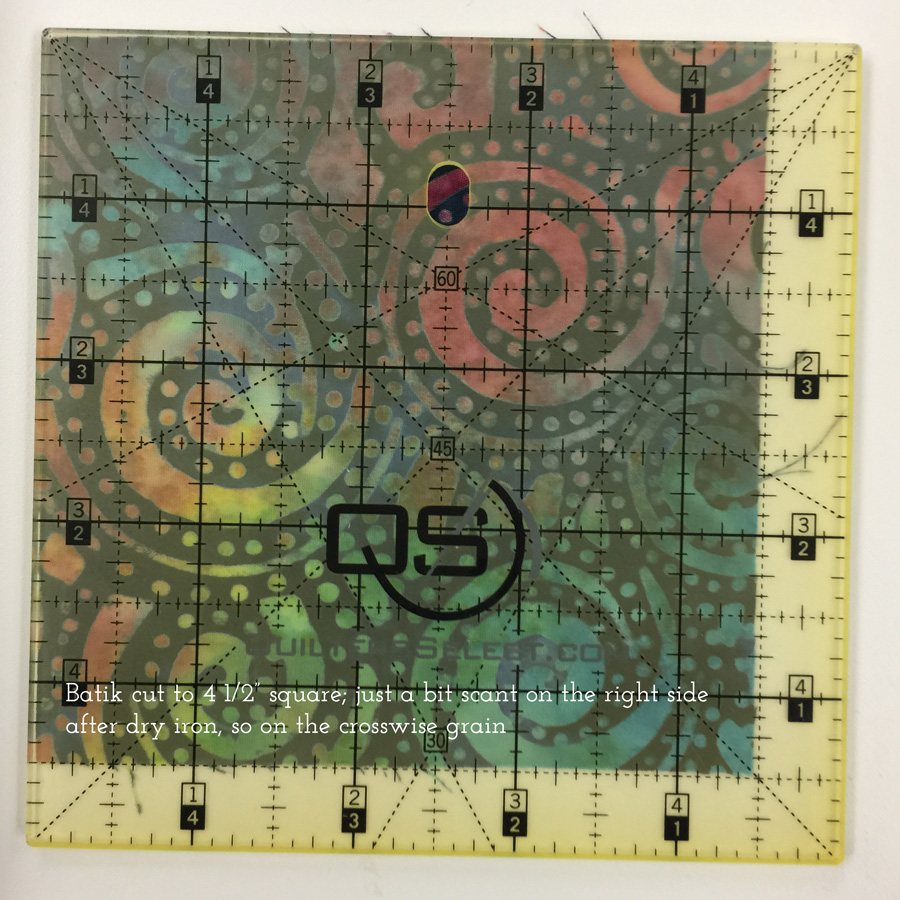

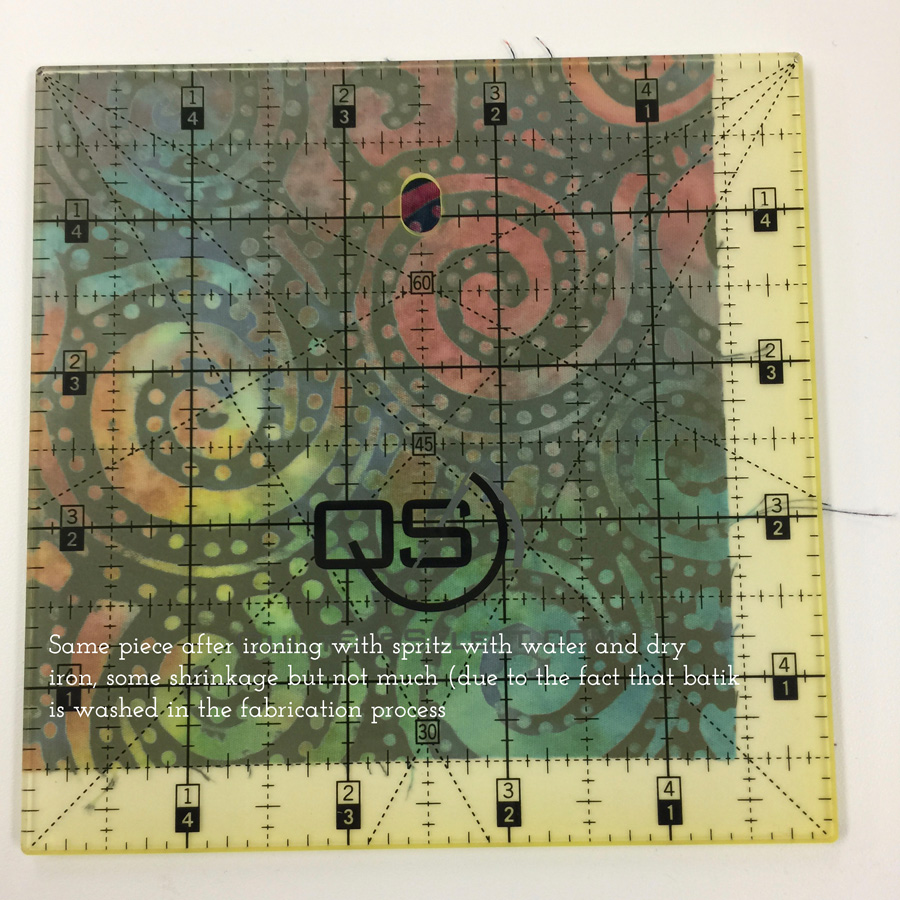

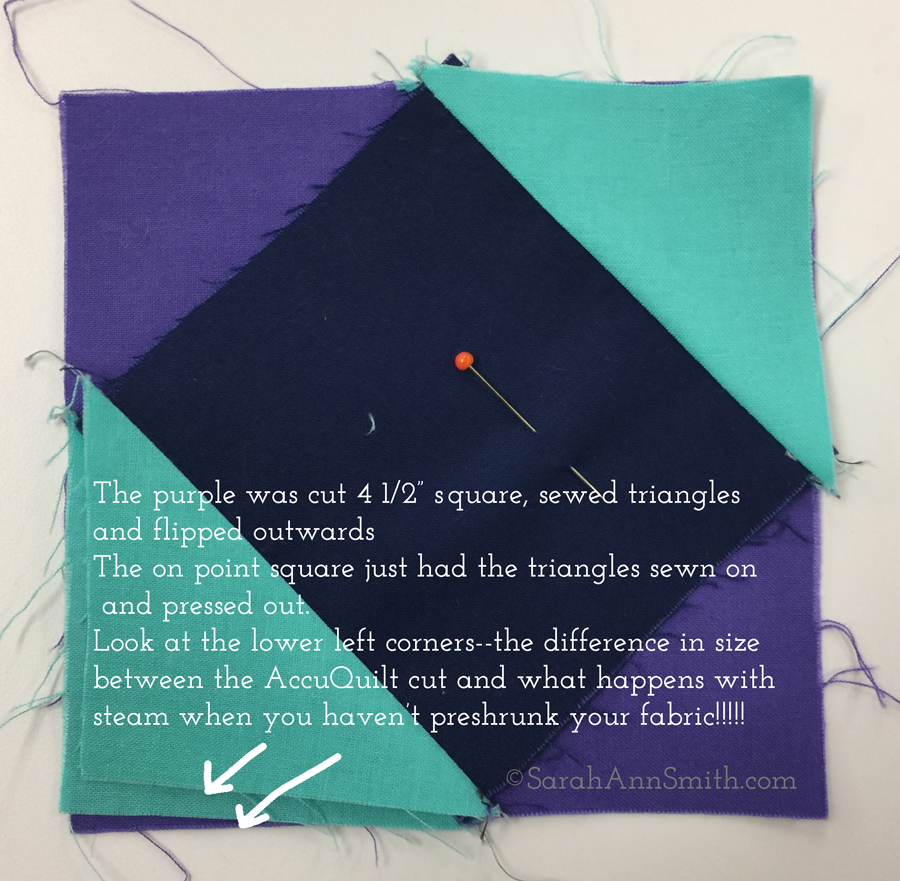

Preshrink all fabrics!

NOTE: Yardage is to make two floor and two toss pillows. Additional materials (zippers, foam and so on) as well as cutting and construction details in the free PDF show measurements and how to make each pillow.

Available now–ask your local shop to order it

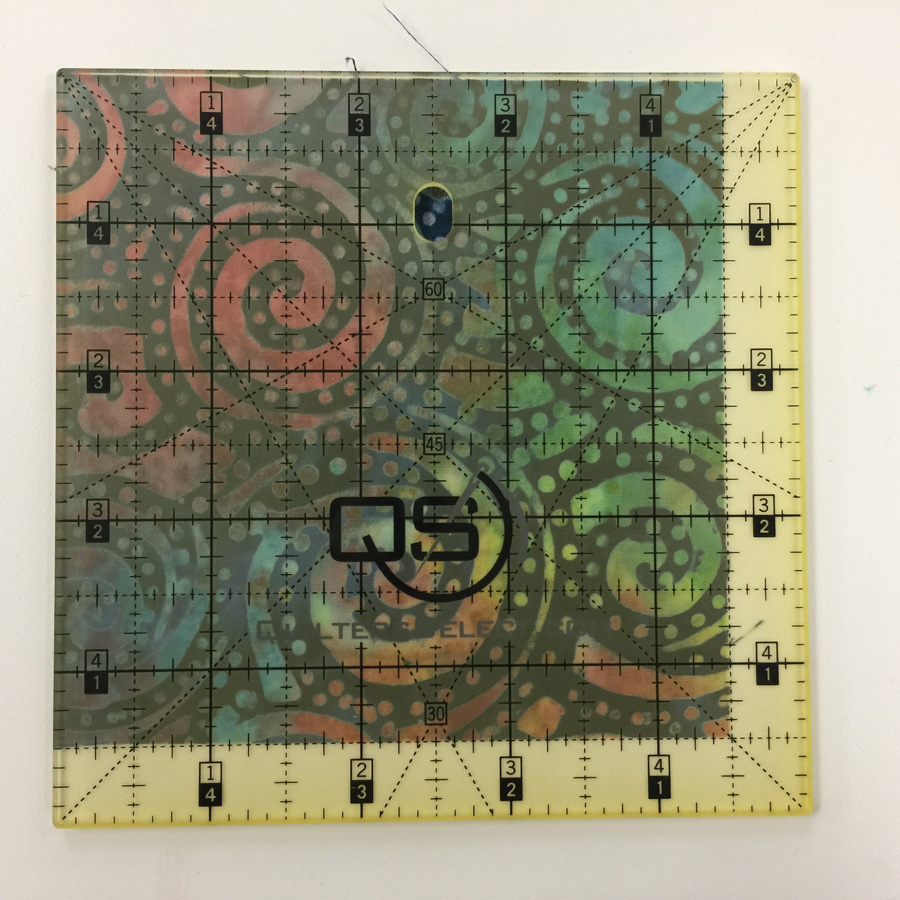

- Focus Fabric 1: Space Pals Black 3/4 yard (will yield two 19” center squares)

- Focus Fabric 2: SuperFred Grey 3/4 yard (will yield two 19” center squares)

- Solids:

- Yellow 1/2 yard

- Apricot 1/2 yard

- Acid 1/2 yard

- Lilypad 1/2 yard

- OPTION: you can use the same fabric for all of the sides if you prefer

- Boxing / sides fabric: Galactic Black 2 yards